Table Of Content

Examining each factor individually would require a tremendous amount of time and resources. Using DOE enables the experimenter to examine multiple factors at once, including the effect of interactions between factors, reducing the required number of runs, thus saving time and valuable resources. The engineering team applied a factorial design approach to investigate several factors simultaneously, including welding temperature, pressure, and duration. The objective was to identify the optimal conditions that consistently produced welds meeting strength standards while minimizing resource consumption. Taguchi, a Japanese engineer, discovered and published a lot of the techniques that were later brought to the West, using an independent development of what he referred to as orthogonal arrays.

Optimization: achieving the best outcome

Kishen in 1940 at the Indian Statistical Institute, but remained little known until the Plackett–Burman designs were published in Biometrika in 1946. R. Rao introduced the concepts of orthogonal arrays as experimental designs. This concept played a central role in the development of Taguchi methods by Genichi Taguchi, which took place during his visit to Indian Statistical Institute in early 1950s. His methods were successfully applied and adopted by Japanese and Indian industries and subsequently were also embraced by US industry albeit with some reservations. The example described below is a simple experiment meant only to demonstrate the four steps of a basic Design of Experiments. Using DOE on your processes will most likely involve several input factors (X) and multiple interactions (S).

Space filling designs

The output responses considered are “taste” and “crust formation.” Taste was determined by a panel of experts, who rated the cake on a scale of 1 (worst) to 10 (best). Crust formation is measured by the weight of the crust, the lower the better. So, the design doesn’t include the high-order interactions with each other, which drastically reduces run numbers. There’s also a whole other way of doing designs, where you use software to create a bespoke design to your exact requirements. These are called optimal designs, and it’s a topic for another day. You can visualize, explore your model and find the most desirable settings for your factors using the JMP Prediction Profiler.

Experimental designs after Fisher

Use Of Design Of Experiments Screening To Select Resins For Monoclonal Antibody Purification - BioProcess Online

Use Of Design Of Experiments Screening To Select Resins For Monoclonal Antibody Purification.

Posted: Fri, 09 Jun 2023 18:25:37 GMT [source]

Project management involves planning and organizing business resources to realize the best possible process and achieve operational excellence. Get to know about salaries and factors affecting six sigma black belt salary and the skills required to have an incremental effect on your pay scale. This comprehensive Lean Six Sigma Bootcamp enables you to master agile management, Lean Six Sigma Black Belt, Lean Six Sigma Green Belt, and tools such as Jira and Minitab. Besides offering classes led by industry experts, the course gives you hands-on experience with real-life projects. Six Sigma has several other vital components like DOE Design of Experiments.

Use screening experiments to reduce cost and time

This paper presents the application of an advanced quality management tool, the design of experiments (DOE), in order to characterise a new material (carbon fibre-reinforced polyamide) used in the 3D printing process. The study focuses on the definition of optimal 3D printing parameters, such as nozzle size, temperature, print speed, layer height and print orientation, to achieve desired mechanical properties. The results show that layer height and print orientation have a significant effect on mechanical properties and printing time.

Applied Statistics: Data Analysis

Once you’ve identified the best potential factors, you can do a full factorial with the reduced number of factors. One of the most important requirements of experimental research designs is the necessity of eliminating the effects of spurious, intervening, and antecedent variables. But there could be a third variable (Z) that influences (Y), and X might not be the true cause at all. The same is true for intervening variables (a variable in between the supposed cause (X) and the effect (Y)), and anteceding variables (a variable prior to the supposed cause (X) that is the true cause).

We change the experimental factors and measure the response outcome, which in this case, is the yield of the desired product. Using the COST approach, we can vary just one of the factors at time to see what affect it has on the yield. A full factorial design provides information about all the possible interactions. Fractional factorial designs will provide limited interaction information because you did not test all the possible combinations. But, what if you aren’t able to run the entire set of combinations of a full factorial? What if you have monetary or time constraints, or too many variables?

main types of DOE designs, explained

Optimization of HEK 293 and CHO-S Cell Growth by Supplementation of Non-Animal Derived Components Using ... - BioProcess Insider

Optimization of HEK 293 and CHO-S Cell Growth by Supplementation of Non-Animal Derived Components Using ....

Posted: Sat, 02 Mar 2024 06:39:01 GMT [source]

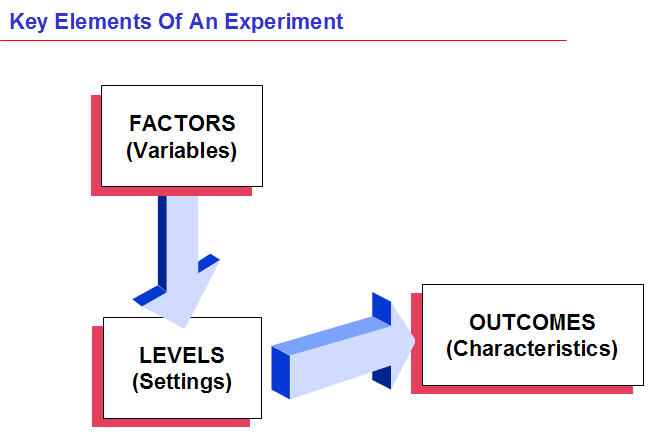

By changing multiple inputs at the same time, DOE helps to identify important interactions that may be missed when experimenting with only one factor at a time. We can investigate all possible combinations (full factorial) or only a portion of the possible combinations (fractional factorial). Design of Experiments (DOE) is a Six Sigma tool that helps project teams determine the effects that the inputs of a process have on the final product. Once Design of Experiments identifies the critical inputs of the process, it helps project teams understand the impact that modifying the variables will have on process performance. Aliasing forms the foundation of fractional factorial designs—and it’s something that you have to bear in mind when assessing them.

The design you choose will inform your analysis

FMCG industry is a part of consumer goods industry that includes all the products which are sold to the general public by any means such as retail stores, internet or by phone. These are mostly used by the consumers in their daily life and may include food, drinks, health and hygiene, cosmetics, household appliances, among others. DoE helps in comparing alternatives or options to get the response where price will be cheaper but does not compromise on quality.

DOE is about creating an entity of experiments that work together to map an interesting experimental region. So with DOE we can prepare a set of experiments that are optimally placed to bring back as much information as possible about how the factors are influencing the responses. DOE also identifies and explores the interactions between those factors.

In order to fully comprehend the power of DOE, it’s helpful to have an understanding of more commonly used approaches, such as investigating a single factor at a time. Outcomes are helpful in improving the process when they can be measured in quantitative terms, rather than in qualitative attributes. A response that is quantifiable makes the experiment well suited to the additional scrutiny of statistical regression techniques. Understand the complexities of ‘sampling bias’ in our comprehensive guide, detailing its impact on statistical analysis and data science. Analysis of the experimental results revealed that welding temperature and pressure were the most significant factors influencing joint strength, with a notable interaction effect between them. Surprisingly, the duration had a lesser impact within the tested range.

Although we know inputs and conditions will change, in our example it's reasonable to assume our existing process is “good enough.” A future blog will look at what happens when you don’t know where to start. We can use the knowledge obtained from bacterial experiments to inform the conditions needed for expression in yeast. But we shouldn't expect the transfer from prokaryotic to eukaryotic lines to be straightforward. This guide will explore the benefits, factors, and challenges of measuring training effectiveness and list the steps you’ll need to properly evaluate your training program. Perform a DoE to optimize any procedure in your workplace and integrate your experimentation with SafetyCulture. A powerful tool used by multiple industries in performing a more convenient and efficient way to monitor, collect, record, inspect, and audit data.

So the problem with the COST approach is that we can get very different implications if we choose other starting points. We perceive that the optimum was found, but the other— and perhaps more problematic thing—is that we didn’t realize that continuing to do additional experiments would produce even higher yields. For example, in the first experimental series (indicated on the horizontal axis below), we moved the experimental settings from left to right, and we found out that 550 was the optimal volume. This article will explore two of the common approaches to DOE as well as the benefits of using DOE and offer some best practices for a successful experiment. The responses we are looking for in this experiment are the yield, the weight, and the taste of the strawberries.

No comments:

Post a Comment